| Background and Goals | 2,3-butanediol (BDO) is gaining attention in the global market as an intermediate product for several applications, such as liquid fuel or as a fuel additive. It can be produced through fermentation in low concentrations (<10 wt%). Therefore, BDO separation/concentration is required for subsequent catalytic upgrading. However, separation of 2,3-BDO poses many challenges due to its inherent characteristics, such as its high affinity with water and high boiling point. A common commercial separation/concentration technology for BDO involves evaporation and multi-stage distillation, both of which are energy intensive, and the high distillation temperatures (130-165 °C) can produce oligomers that require subsequent hydrogenation. Further, some components in the fermentation broth can inhibit or poison BDO upgrading catalysts and require removal upstream. The goal of this work was to develop low-cost and energy-efficient separation technologies, supported by techno-economic analysis (TEA), life cycle assessment (LCA), and computational modeling, to recover BDO from fermentation broth. |

| Technical Approach | The Consortium has investigated multiple approaches to recover 2,3-BDO from fermentation broth because current industrial methods, involving both distillation and hydrogenation, are energy-intensive. TEA and LCA were integrated to evaluate the tradeoffs related to separation cost, energy intensity, and sustainability of the potential approaches. Computational simulations were also integrated to provide guidance on improving the materials and processes. Initial efforts focused on a hybrid approach including pervaporation; however, TEA indicated that pervaporation could not achieve energy/cost savings in comparison to the state of technology. This motivated investigation of 3 alternative, non-thermal approaches to extract and recovery 2,3-BDO: 1) solvent extraction followed by membrane separation or evaporation and BDO upgrading to fuel, 2) reactive extraction to produce dioxolane, which can be subsequently upgraded to fuel products, and 3) an extension of (2) to include the reaction of the dioxolane back into BDO and distillation of BDO from the ketone/aldehyde. Analysis of these approaches at the both the separation process and biorefinery levels guided work to the current approach, which proposes membrane assisted liquid-liquid extraction (MLLE) to effectively and economically separate, concentrate, and purify BDO. |

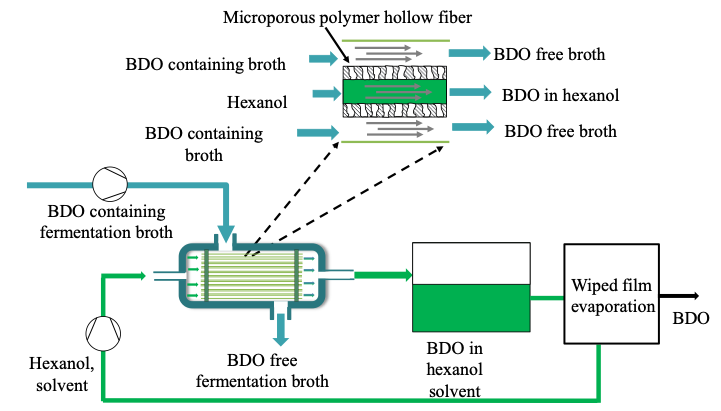

| BDO Separations and Purification | Novel 2,3-BDO recovery approaches were investigated using conventional separatory funnels as well as a continuous liquid-liquid extraction (LLE) system with multistage, membrane-based extraction. A range of solvents (1-Butanol, oleyl alcohol, 2-Ethyl-1-hexanol, 1-Hexanol, and ethyl acetate) were used to extract BDO from an aqueous stream. A porous hydrophobic membrane was selected based on pore size, wettability, and chemical compatibility. Preliminary data showed that the membrane contactor can separate BDO from aqueous solution using hexanol in a continuous mode of operation. MLLE is an energy-efficient scalable approach that provides high surface area for contact between the organic and aqueous phase and prevents emulsion formation. |

| Economic and Computational Modeling | An initial technical and economic assessment for removing charged species, inorganic salts, and organic acids from BDO fermentation broth was completed. A sub-model for determining the thermodynamics and basic processing performance for the preconcentration of 2,3-BDO using multistage membrane pervaporation was also developed. This model helped guide research and development toward the membrane-assisted LLE approach. In the case of LLE, TEA results also indicated that solvent drying to remove residual water in the extraction solvent is important to realize energy savings. A computational screening of LLE solvents was performed using ab initio calculations, which were complemented using a random forest machine learning algorithm. This screening revealed that 1-Butanol and 1-Hexanol are promising candidates for solvent extraction of 2,3-BDO from water. Additionally, atomistic modeling using ab initio calculations and classical molecular dynamics suggest that sulfonation of polybenzimidazole (PBI) membranes effectively modifies the interaction between PBI polymer chains, 2,3-BDO, and water. The covalently bound sulfonated PBI (sPBI) exhibits an improved water/2,3-BDO separation selectivity, which can be experimentally synthesized by acid treatment followed by heat treatment. |

| Figures |

Figure 1. Schematic of BDO separation using membrane contactor system |