| Highlights |

Advanced adsorbent materials enable specific recovery of volatile bioproducts from fermentor off-gas at ambient temperature with minimal water contamination. Efficient mechanical desorption and high material longevity result in predicted cost savings of >20% when compared to conventional condensation and distillation. |

| Context and Goals | A variety of high potential bioproducts are volatilized to bioreactor off-gases during aerobic fermentation. Efficient recovery of these molecules requires development of innovative, low-cost, and efficient volatile product capture strategies. Baseline approaches rely on in situ organic overlays or on low temperature condensation of fermenter off-gas, but these methods are costly, energy intensive, and necessitate additional dewatering or solvent recovery steps. Retention of hydrophobic products in the fermentor also increases product toxicity, reducing production rates and achievable titers. ANL researchers have developed technology to passively capture volatile products with minimal water co-capture using advanced adsorbent materials. These materials were adapted based on successful application for liquid-liquid capture within active fermentation processes. After 3 years, results from ≥3 industrial-derived SAF bioprocesses (with a 300-L scale demonstration) will highlight cost advantages of the alternative adsorptive approach and demonstrate near-quantitative bioproduct capture. This approach results in purities allowing for immediate use (≥ 95% pure SAFs or precursors), continuing broad industrial interest. |

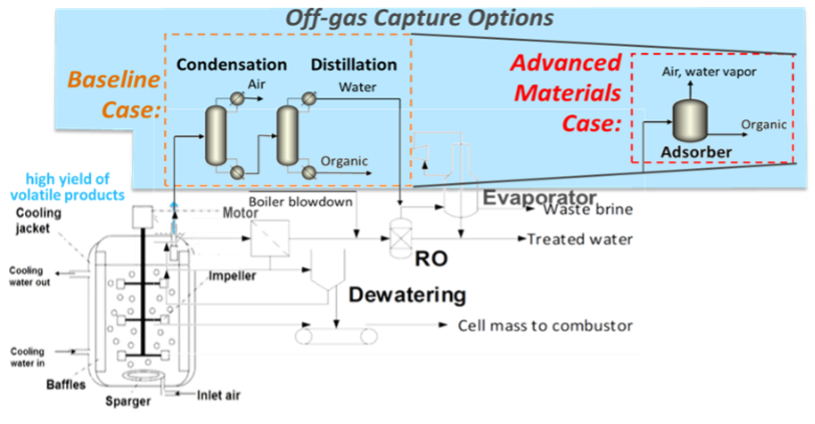

| Technical Approach | Current recovery methods for volatile product capture utilize condensation and distillation to separate organic products from condensed vapors (Figure 1), requiring multiple heating and cooling steps. The adsorbent-based advanced materials approach works at near-ambient temperatures with tunable surfaces specifically targeting bioproducts, minimizing energy use. This approach allows the adsorbent to be placed in-line during the fermentation process and subsequently removed after collecting the product in high purity. The adsorbent can then be replaced in-line, or a second parallel system can be utilized. This allows for maximum product adsorption as the fermentation and production process can continue endlessly. |

| Accomplishments and Results | To date, advanced xerogel materials developed for liquid-liquid product capture were successfully transitioned towards capture of volatile products. They accommodate high gas flows and high moisture content, characteristic of fermentation off-gasses, with minimal pressure drop. Via scalable cartridge designs, recoveries of >83% have been achieved, even for low boiling bioproducts unrecoverable via condensation alone. These high yield recoveries are coupled with minimal water co-adsorption (typical non-specific condensation << 5%), well below the initial goal of 50% product purities. These successes were realized by increasing product-adsorbent resonance times within the advanced materials to allow for surface interactions and capture with high gas flow rates. Additionally, desorptive recovery of product from the material via low energy compression was optimized, demonstrating unwavering materials performance for over 50 adsorptive and desorptive cycles. High durability further reduces the cost of this approach, with predicted economic and environmental savings exceeding 20% when compared to baseline technology across all scenarios modeled to date. Multiple product classes are currently under investigation for coupled fermentation and off-gas capture, including collaborations with Praj Matrix and the US Navy to scale production of volatile sustainable aviation fuel precursors. |

| Computational-Guided Advancements | Atomistic simulations aided with xerogel surface modifications for improved product capture and selectivity for volatile bioproduct recoveries from humid gas streams. Density-functional theory (DFT) uncovered differences in adsorption free energies of bioproducts and water as the functional groups on the xerogel surface are altered, e.g., alkyl (C3-C8), vinyl, and phenyl groups. Classical molecular dynamics predicted the transport properties of bioproducts in xerogel models and suggest that alkyl chains >C3 (propyl to octyl) enable higher selectivity for many target compounds when compared to shorter alkyl, vinyl, and phenyl groups. |

| Figures |

Figure 1. Volatile bioproducts from bioreactors with off-gas capture operations (blue) using the baseline technology (orange) or more efficient adsorbent-based recovery (red). |