| Highlights |

Individual lignin monomers can be separated using CCC. The CCC process is more energy-efficient and economical than Simulated Moving Bed (SMB). |

| Separation Challenges for Lignin Valorization | Separation processes, both old and new, depend on mixture physical properties. Accurate and practical physical property models are required to accurately model and compare separation processes. Data from bio-relevant compounds and mixtures are often scant, unreliable, or unavailable. In general, reliance on property estimation methods, which may not be relevant to bio-relevant compounds and mixtures, result in low confidence process analysis results. Developing adequate thermodynamic models requires an understanding of the process, the mixtures involved, and the sensitivity of the process to uncertainty in physical properties. Developing adequate thermodynamic models begins with determining whether sufficient data exists; and if insufficient data exists, evaluating the impact the lack of data on the analysis. If sufficient data exists, the next question is determining whether existing models can adequately represent the data. If not, the existing models must be modified or new models developed. The final step in the process is fitting the model to the available data. |

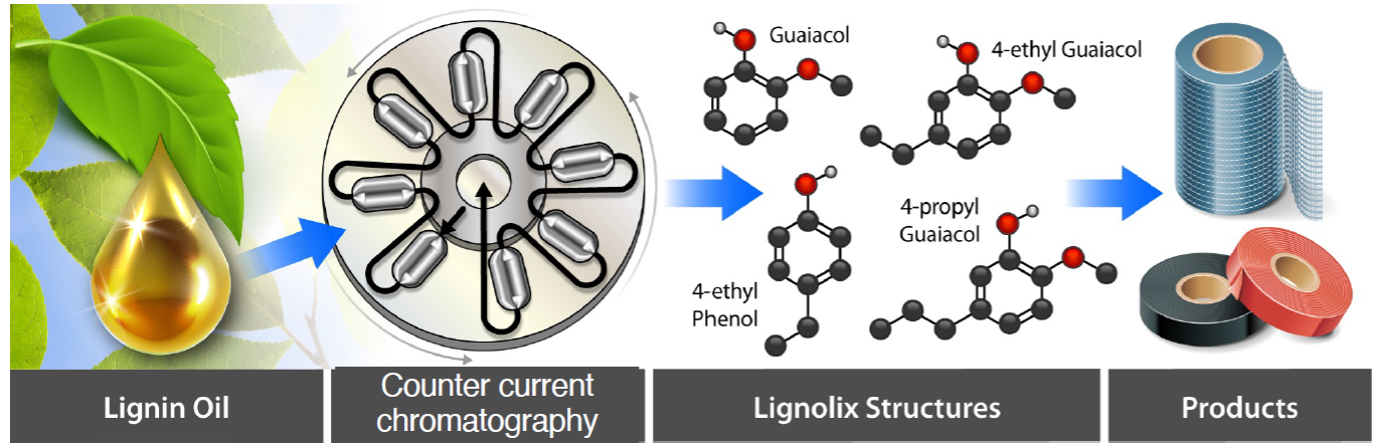

| CCC is Chromatography That Uses a Liquid Stationary Phase | CCC is a dynamic liquid-liquid chromatography process where the upper or lower phases of a biphasic solvent system can be used as the stationary phase of CCC. With the unique planetary motion of CCC, hundreds to thousands of mixing and settling events can occur in a small column. As a result, lignin-derived compounds can be separated based on their different polarities and solubilities in biphasic solvent systems. CCC can handle high feed loadings and solids in the feed, enables full product recovery with various elution modes, uses inexpensive solvents for the stationary phase, and avoids resin fouling issues |

| Lignin-Derived Monomers From the Lignin Oil Using CCC | With CCC, lignin-derived compounds were separated from lignin oil produced from reductive catalytic fractionation (RCF). Phenolic monomers were separated from oligomers using biphasic solvent systems in CCC, with yields and purities of individual aromatic monomers, both up to 99%. Tuning the polarity of the solvent can also separate dimers from higher molecular weight compounds. |

| Mathematical Model for CCC Optimization | The Cell Utilized Partition (CUP) model was developed by NREL and PNNL from basic separation (LLE) measurements. The CUP model can predict the chromatograms for various elution modes of CCC or for a general liquid-liquid chromatography process. Accordingly, the model can be used to narrow down the most viable feedstocks to target with the technology and to optimize the process for high purity, yield, and productivity. The details of the model can be found in Choi et al. (2022). The CUP model source codes are publicly available on GitHub. |

| Figures |  Figure 1. Overview of the downstream process using CCC. Lignin-derived chemicals are separated from lignin oil using CCC. The purified phenolic monomers can be used for high-value products. |