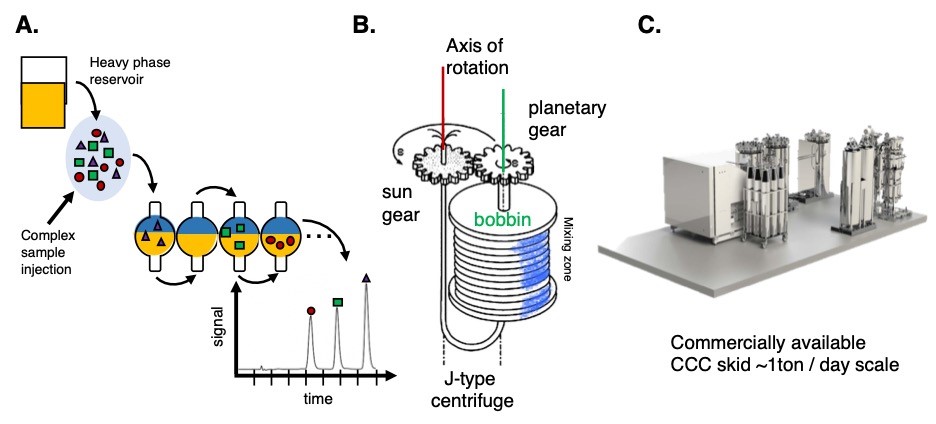

| Overview | CCC is a scalable chromatographic technology that uses the counter current motion of a two-phase liquid-liquid system to generate a chromatographic effect on the solvated compounds, separating them into pure components. It is an emerging technology with recently developed instruments capable of ton / day processing levels with even larger processing scale available in novel modes of operation. Consortium researchers are advancing CCC for the recovery of high value co-products from chemically complex streams such as lignin streams, hydrothermal liquefaction oils, catalytic fast pyrolysis oils and more. In comparison to Simulated Moving Bed (SMB) technology CCC has advantages in that it can handle solids in the feed without any upfront filtration, and has a lower solvent load and energy consumption. This makes CCC an ideal solution for recovering coproducts direct from traditionally intractable biorefining streams. |

| National Laboratories | National Renewable Energy Laboratory (NREL) Pacific Northwest National Laboratory (PNNL) |

| Additional Information |