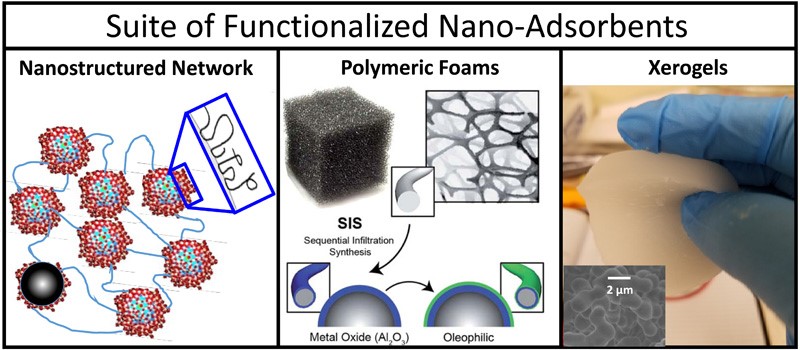

| Overview | These separations approaches apply advanced materials with high selectivity and binding capacity for removal of chemical species from active fermentation systems. The materials target not only bioproducts (fuels and chemicals) that are the output of bioconversion processes, but also toxins and inhibitors that deter the cost-effectiveness of the biocatalytic routes. A suite of technologies (e.g., surface-treated nanostructured networks, environmentally benign adsorbent foams, and/or other developing molecular-directed approaches) target toxins inherent to acid or hydrothermal pretreatment of lignocellulosic materials or inhibitors produced during fermentation that impair the performance of enzymes. The economic impact of the approaches depends heavily upon the longevity of the materials and how many times they can be reused. Their implementation is projected to increase production rates, extend biochemical catalyst lifetimes, and enable reactor-integrated separations and process intensification. |

| National Laboratory | Argonne National Laboratory (ANL) |

| Additional Information |

S.B. Darling, J.W. Elam, A.U. Mane, and S.W. Snyder, Functionalized foams, US Patent Application 15/644,569, 2018.E. Barry, A.U. Mane, J.A. Libera, J.W. Elam, S.B. Darling, Advanced oil sorbents using sequential infiltration synthesis, Journal of Materials Chemistry A, 5 (6), 2929-2935, 2017. S.B. Darling, J.W. Elam, and A. Mane, Oleophilic foams for oil spill mitigation, US Patent Application 14/967,021, 2016. Brotzman, R.W., Surface Treatment of Nanoparticles to Control Interfacial Properties and Method of Manufacture, U.S.P. Office, 7,303,819, 2009. Y.J. Lin, R.W. Brotzman, S.W. Snyder. Compositions and methods for direct capture of organic materials from process streams. US Patent Application 132/962,480, 2013. |