| Overview |

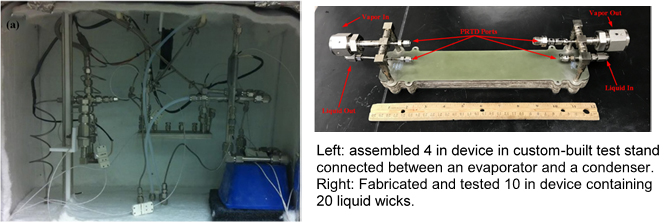

PNNL has unique capabilities in micro-channel-based distillation, with demonstrated heights of a theoretical plate (HETP) of < 3.3 millimeters. This is nearly two orders of magnitude less than commercial structured packings that report HETP values of 300 to 600 millimeters. The technology platform has been applied to close-boiling-point component separations, at both elevated temperatures and cryogenic temperatures, including isotope enrichment. The technology is also amenable to reactive distillation approaches.The microchannel distillation concept involves thin, porous wicking structures that transport liquid through the device in one direction while gas flows countercurrently in adjacent vapor channel. Capillary forces prevent vapor intrusion into the wicks. Vapor exiting the device is condensed and refluxed back to the microchannel device, thereby creating a recirculating flow necessary for total reflux distillation. The alternating configuration of vapor channel and liquid wicks allows mass transfer to occur in both directions along the flow length which enhances the characteristic mass transfer time by a factor of 4. The current microchannel distillation device is 10 inches long, 1.6 inches wide, and is comprised of 20 thin (0.004 inches) liquid wicks stacked alternately between 21 thicker (0.02 inches) vapor channels. |

| National Laboratory | Pacific Northwest National Laboratory (PNNL) |

| Additional Information |

|